-

1.What is the size, current and voltage rating of this connector?

The Male DVI Connector is a widely used connector in the audiovisual industry that allows for high-quality digital video and audio transmission. Here is a detailed introduction to the size, current rating, and voltage rating of the Male DVI Connector:

Size: The Male DVI Connector comes in different sizes, including DVI-A, DVI-D, and DVI-I. The DVI-A connector is the analog-only variant and has 17 pins arranged in three rows. The DVI-D connector is the digital-only variant and has 24 pins arranged in three rows. The DVI-I connector is the integrated variant and has all the pins required for both analog and digital signals.

Current Rating: The Male DVI Connector does not have a specific current rating since it primarily carries digital video and audio signals. However, the pins and contacts within the connector are designed to handle the low-level electrical currents required for transmitting these signals without any significant power loss or distortion.

Voltage Rating: The Male DVI Connector is typically used for transmitting digital video and audio signals, which operate at low voltages. The voltage rating of the connector is not specifically defined since it depends on the specific application and the devices connected. However, it is commonly used for transmitting signals in the range of 0.3 to 0.5 volts.

Compatibility: The Male DVI Connector is compatible with various devices, including computers, monitors, projectors, and televisions. It is commonly used for connecting digital displays to video sources and supports high-resolution video signals, making it popular in applications that require high-quality visuals, such as gaming, multimedia production, and professional presentations.

Signal Transmission: The Male DVI Connector supports the transmission of digital video signals, including DVI Single-Link and DVI Dual-Link formats. It can carry uncompressed video signals and supports various video resolutions, including Full HD (1080p), 2K, and 4K resolutions. Some variants of the Male DVI Connector also support the transmission of digital audio signals.

Quality and Reliability: The Male DVI Connector is known for its high-quality construction, which ensures reliable signal transmission and durability. It is designed to minimize signal loss and interference, resulting in clear and stable video and audio quality. The connectors are typically made of high-quality materials such as metal shells and gold-plated contacts, which provide excellent conductivity, corrosion resistance, and long-term reliability.

In conclusion, the Male DVI Connector comes in different sizes, including DVI-A, DVI-D, and DVI-I, and is primarily used for transmitting digital video and audio signals. It is compatible with various devices and supports high-resolution video signals. The connector is known for its high-quality construction, ensuring reliable signal transmission and durability.2. Are there different socket types to choose from?

Yes, there are different socket types available for the Male DVI Connector. The Male DVI Connector is designed to mate with its corresponding Female DVI Connector, creating a secure and reliable connection for digital video and audio transmission. Here are the different socket types available for the Male DVI Connector:

DVI-A Socket: The DVI-A socket is the analog-only variant of the Male DVI Connector. It consists of 17 pins arranged in three rows. The DVI-A socket is used for transmitting analog video signals and is commonly found in older devices that do not support digital video.

DVI-D Socket: The DVI-D socket is the digital-only variant of the Male DVI Connector. It consists of 24 pins arranged in three rows. The DVI-D socket is used for transmitting digital video signals and is commonly found in modern devices that support digital video. It provides a high-quality, noise-free digital video transmission.

DVI-I Socket: The DVI-I socket is the integrated variant of the Male DVI Connector. It consists of all the pins required for both analog and digital signals. The DVI-I socket can transmit both analog and digital video signals, making it compatible with a wide range of devices. It is commonly used in applications where both analog and digital video signals need to be supported.

Each socket type has a specific configuration of pins that ensures proper alignment and connection with the matching Female DVI Connector. It is important to select the correct socket type to ensure compatibility and optimal performance of the Male DVI Connector.

In addition to the different socket types, Male DVI Connectors are available in various sizes and form factors, such as standard size, mini, and micro. These different sizes and form factors are designed to accommodate different space constraints and device requirements.

In conclusion, the Male DVI Connector is available in different socket types, including DVI-A, DVI-D, and DVI-I. Each socket type is designed to accommodate specific types of video signals and is compatible with corresponding Female DVI Connectors. It is important to choose the correct socket type to ensure compatibility and optimal performance.3.Main purposes and application areas

The Male DVI Connector is a widely used connector in the audiovisual industry that allows for high-quality digital video and audio transmission. It plays a crucial role in connecting various devices, such as computers, monitors, projectors, and televisions, to display digital content. Here is a detailed introduction to the main purposes and application areas of the Male DVI Connector:

Main Purposes:

Digital Video Transmission: The primary purpose of the Male DVI Connector is to transmit digital video signals. It supports high-resolution video formats, including Full HD (1080p), 2K, and 4K resolutions. The connector ensures a stable and reliable transmission of uncompressed video signals, resulting in clear and vibrant visuals.

Digital Audio Transmission (Some Variants): In addition to video, certain variants of the Male DVI Connector also support the transmission of digital audio signals. This allows for a complete multimedia experience by transmitting both high-quality video and audio signals through a single connector.

High-Quality Signal Transmission: The Male DVI Connector is designed to minimize signal loss and interference, ensuring a high-quality transmission of video and audio signals. It provides excellent image clarity, color accuracy, and video playback without any distortion or degradation.

Application Areas:

Gaming: The Male DVI Connector is widely used in gaming setups to connect gaming consoles or computers to monitors or televisions. It supports high-resolution gaming and ensures a smooth and immersive gaming experience with minimal input lag.

Multimedia Production: The Male DVI Connector finds extensive use in multimedia production environments such as video editing studios and post-production facilities. It allows for the accurate display of high-resolution video content, ensuring precise color grading and accurate visual representation.

Professional Presentations: In professional settings such as conference rooms and boardrooms, the Male DVI Connector enables the connection of laptops or presentation systems to projectors or large displays. It ensures crisp and clear visuals, enhancing the effectiveness of presentations and meetings.

Digital Signage: The Male DVI Connector is commonly used in digital signage applications, where it facilitates the connection between media players and digital displays. It ensures the delivery of high-quality content, enabling dynamic and engaging visual communication in retail stores, airports, stadiums, and other public spaces.

Home Entertainment: The Male DVI Connector is utilized in home theater systems to connect DVD players, Blu-ray players, or media streaming devices to high-definition televisions or projectors. It allows for the transmission of high-quality video and audio signals, providing a cinematic experience in the comfort of one's home.

In conclusion, the Male DVI Connector serves as a reliable and versatile connector for digital video and audio transmission. Its main purposes include transmitting digital video signals, supporting digital audio transmission (certain variants), and ensuring high-quality signal transmission. It finds applications in gaming, multimedia production, professional presentations, digital signage, and home entertainment, enhancing the visual experience in various settings.4. How durable and reliable is it?

The Male DVI Connector is known for its durability and reliability, making it a popular choice in the audiovisual industry. Here is a detailed introduction to its durability and reliability:

Construction: The Male DVI Connector is typically made with high-quality materials such as metal shells and gold-plated contacts. These materials provide excellent conductivity, corrosion resistance, and long-term durability. The connectors are designed to withstand frequent plugging and unplugging without compromising their structural integrity.

Signal Transmission: The Male DVI Connector is designed to minimize signal loss and interference, ensuring a reliable transmission of digital video and audio signals. The pins and contacts within the connector are precisely engineered to maintain a stable connection, resulting in clear and stable video and audio quality. The connector's design ensures that there is no signal degradation or distortion during transmission.

Robust Design: The Male DVI Connector is designed to withstand the rigors of everyday use. It is built to be resistant to physical stresses, including bending, twisting, and accidental impacts. The connectors are often tested to meet industry standards for durability and reliability, ensuring that they can withstand the demands of professional settings.

Longevity: The Male DVI Connector is built to last. The high-quality materials used in its construction and the robust design ensure that it can withstand the test of time. The connectors are resistant to wear and tear, maintaining their performance even after prolonged use. This longevity makes the Male DVI Connector a cost-effective choice for individuals and businesses.

Industry Standards: The Male DVI Connector complies with industry standards for durability and reliability. It is often tested and certified by regulatory bodies to ensure that it meets the required performance standards. These certifications provide assurance that the connector will perform reliably under various conditions.

Customer Feedback: The Male DVI Connector has received positive feedback from users for its durability and reliability. Many customers have reported using the connector for extended periods without experiencing any issues. This feedback is a testament to the connector's quality and ability to deliver consistent performance.

In conclusion, the Male DVI Connector is known for its durability and reliability. Built with high-quality materials and a robust design, it ensures a stable and uninterrupted transmission of digital video and audio signals. The connector's longevity and compliance with industry standards make it a trusted choice for professionals and individuals seeking a reliable audiovisual connection.5. How does it work?

The Male DVI Connector is an essential component in connecting devices that require digital video and audio transmission. It works by establishing a secure and reliable connection between the Male DVI Connector and its corresponding Female DVI Connector. Here is a detailed explanation of how it works:

Connector Design: The Male DVI Connector is designed with a specific configuration of pins that correspond to the pins in the Female DVI Connector. These pins ensure proper alignment and connection between the two connectors. The connector is typically made of metal shells with gold-plated contacts, which provide excellent conductivity and corrosion resistance.

Digital Video Transmission: The Male DVI Connector is primarily used for transmitting digital video signals. It supports high-resolution video formats, including Full HD (1080p), 2K, and 4K resolutions. The digital video signals are transmitted through the pins in the connector, ensuring a stable and reliable transmission. This results in clear and vibrant visuals on the connected display device.

Signal Transmission: The pins and contacts within the Male DVI Connector are precisely engineered to maintain a stable connection and minimize signal loss and interference. The digital video signals are transmitted as binary data through the pins, ensuring accurate representation of the video content. The connector's design ensures that there is no signal degradation or distortion during transmission.

Single Link and Dual Link Variants: The Male DVI Connector comes in two variants: Single Link and Dual Link. The Single Link variant consists of 18 pins arranged in three rows, while the Dual Link variant consists of 24 pins arranged in three rows. The Dual Link variant supports higher resolutions and provides a higher bandwidth for transmitting digital video signals.

Audio Transmission (Some Variants): Certain variants of the Male DVI Connector also support the transmission of digital audio signals. These variants have additional pins dedicated to transmitting audio signals. This allows for a complete multimedia experience by transmitting both high-quality video and audio signals through a single connector.

Plug and Play: The Male DVI Connector is designed for easy plug-and-play functionality. It can be easily inserted into the corresponding Female DVI Connector without the need for additional tools or adjustments. Once connected, the Male DVI Connector establishes a secure and reliable connection, ensuring a seamless transmission of digital video and audio signals.

In conclusion, the Male DVI Connector works by establishing a secure and reliable connection with the Female DVI Connector. It transmits digital video signals through a specific configuration of pins and ensures a stable and accurate representation of the video content. Certain variants also support the transmission of digital audio signals. With its plug-and-play functionality, the Male DVI Connector provides a convenient solution for connecting devices that require digital video and audio transmission.6. How to install and use?

Installing and using the Male DVI Connector is a straightforward process. Here is a step-by-step guide on how to install and use the connector:

Identify the Male DVI Connector: The Male DVI Connector has pins that correspond to the Female DVI Connector. It is usually made of metal shells and has gold-plated contacts. Familiarize yourself with the connector's appearance and design before proceeding.

Check for Compatibility: Ensure that the devices you want to connect have Female DVI Connectors. The Male DVI Connector is designed to fit into the Female DVI Connector, so it is essential to verify compatibility.

Power Off Devices: Before connecting or disconnecting any cables, it is crucial to power off all devices involved. This ensures safety and prevents any potential damage to the equipment.

Align the Connectors: Take the Male DVI Connector and align it with the Female DVI Connector. The pins on the Male DVI Connector should correspond to the holes in the Female DVI Connector. Make sure the connectors are properly aligned before proceeding to the next step.

Insert the Connector: Gently insert the Male DVI Connector into the Female DVI Connector. Apply even pressure and avoid forcing the connector into the slot. The connectors should fit smoothly together. If there is any resistance, double-check the alignment and try again.

Secure the Connection: Once the connectors are fully inserted, secure the connection by tightening any screws or latches if present. This ensures a secure and stable connection between the devices.

Power On Devices: After the connection is secure, power on the devices. Allow them to boot up and establish a connection. Depending on the devices, you may need to select the appropriate input source or adjust display settings.

Test the Connection: To ensure that the connection is working correctly, check the display on the connected device. Verify that the video and audio, if supported, are being transmitted successfully. If there are any issues, double-check the connection and settings.

Adjust Display Settings: Depending on the devices and preferences, you may need to adjust the display settings. This includes resolution, aspect ratio, refresh rate, and color calibration. Consult the user manuals of the devices for guidance on adjusting the settings.

Disconnecting the Connector: When you need to disconnect the Male DVI Connector, make sure to power off the devices first. Then, gently remove the connector by pulling it straight out. Avoid twisting or bending the connector, as it may cause damage.

In conclusion, installing and using the Male DVI Connector involves aligning and connecting the corresponding Male and Female DVI Connectors. It is essential to ensure compatibility, power off devices before installation, and follow proper procedures for connecting and disconnecting the connector. By following these steps, you can easily install and use the Male DVI Connector to transmit digital video and, in some cases, audio signals between compatible devices.

-

1.What is the size, current and voltage rating of this connector?

The Solder Cup Power D-Sub Connector is a versatile and reliable connector commonly used in various electronic applications. This type of connector is known for its robust construction and ability to handle high power and signal transmission requirements. Here is a detailed introduction to the Solder Cup Power D-Sub Connector:

Size:

The Solder Cup Power D-Sub Connector is available in standard sizes ranging from 9 to 50 pins. The size of the connector is typically determined by the number of pins or contacts it contains. The dimensions of the connector are designed to fit standard D-Sub connector cutouts, making it compatible with a wide range of devices and equipment.

Current Rating:

The Solder Cup Power D-Sub Connector is capable of handling high current ratings, typically ranging from 5 to 40 Amperes per contact. This makes it suitable for applications that require the transmission of power and signals simultaneously. The connector's design ensures efficient power delivery while maintaining a stable electrical connection.

Voltage Rating:

The Solder Cup Power D-Sub Connector is designed to withstand high voltage levels, with voltage ratings typically ranging from 250 to 600 Volts. This allows the connector to be used in applications where high voltage requirements are essential, such as power distribution systems, industrial machinery, and communication equipment. The insulation properties of the connector help ensure safe and reliable operation even at high voltage levels.

Features:

The Solder Cup Power D-Sub Connector features solder cup contacts that provide a secure and stable connection between the connector and the wires or cables. The solder cups are designed to accommodate a wide range of wire gauges, allowing for flexibility in terms of wire size and compatibility. Additionally, the connector is equipped with metal shells for enhanced durability and protection against electromagnetic interference (EMI).

Applications:

The Solder Cup Power D-Sub Connector is commonly used in industrial automation, telecommunications, power distribution, instrumentation, and data communication applications. Its high current and voltage ratings make it ideal for applications that require the transmission of power signals over long distances. The connector is also suitable for harsh environments thanks to its robust construction and reliable performance.

In conclusion, the Solder Cup Power D-Sub Connector is a versatile and high-performance connector designed to meet the demanding requirements of power and signal transmission applications. With its high current and voltage ratings, durable construction, and compatibility with various wire gauges, this connector is a reliable choice for a wide range of electronic and industrial applications.2. Are there different socket types to choose from?

The Solder Cup Power D-Sub Connector is available in different socket types to accommodate various wiring configurations and preferences. Here is a detailed to the different socket types available for the Solder Cup Power D-Sub Connector:

Standard Solder Cups: This is the most common type of socket for the Solder Cup Power D-Sub Connector. It features solder cups that allow wires or cables to be soldered directly onto the connector. This type of socket provides a secure and reliable connection, making it suitable for a wide range of applications.

Insulated Solder Cups: In some applications, it may be necessary to insulate the solder cups to prevent electrical short circuits or to meet specific safety requirements. Insulated solder cups feature a protective insulating material that surrounds the solder cups, providing electrical insulation between contacts. This type of socket ensures proper isolation and prevents accidental contact between adjacent pins.

Screw Terminal Sockets: Screw terminal sockets provide an alternative method for connecting wires or cables to the Solder Cup Power D-Sub Connector. Instead of soldering, wires or cables are secured using screws that clamp onto the stripped ends of the wires. This type of socket is popular for applications where frequent wire changes or connections are required.

IDC (Insulation Displacement Connector) Sockets: IDC sockets offer a convenient and time-saving solution for wire termination. They feature small metal contacts that pierce through the wire insulation, making a reliable electrical connection. IDC sockets eliminate the need for soldering or stripping wire ends, which can save time and reduce the risk of human error during installation.

High-Density Sockets: High-density sockets are designed to accommodate a larger number of pins or contacts in a smaller footprint. These sockets have a higher pin density, allowing for more connections in a limited space. High-density Solder Cup Power D-Sub Connectors are commonly used in applications where space is a premium, such as in aerospace, military, and telecommunications industries.

It's important to note that the availability of different socket types may vary depending on the manufacturer and specific product line. When selecting the Solder Cup Power D-Sub Connector, it is recommended to consult the manufacturer's catalog or datasheet to determine the available socket types and choose the one that best suits your application requirements.

In conclusion, the Solder Cup Power D-Sub Connector offers a range of socket types to accommodate different wiring configurations and installation preferences. Whether you prefer standard solder cups, insulated solder cups, screw terminals, IDC sockets, or high-density sockets, there is a suitable option available to meet your specific needs.3.Main purposes and application areas

The Solder Cup Power D-Sub Connector is a versatile and widely used connector in various industries and applications. It is designed to provide a secure and reliable connection for power and signal transmission. Here is a detailed introduction to the main purposes and application areas of the Solder Cup Power D-Sub Connector:

Main Purposes:

Power Transmission: One of the main purposes of the Solder Cup Power D-Sub Connector is to transmit power efficiently and reliably. It is capable of handling high current ratings, typically ranging from 5 to 40 Amperes per contact. This makes it suitable for applications that require the transmission of power, such as power distribution systems, industrial machinery, and power supplies.

Signal Transmission: In addition to power transmission, the Solder Cup Power D-Sub Connector is also used for signal transmission. It provides a stable and secure connection for transmitting signals between devices and components. This makes it ideal for applications that require the transmission of control signals, data signals, and communication signals.

Industrial Automation: The Solder Cup Power D-Sub Connector is widely used in industrial automation applications. It is commonly found in PLCs (Programmable Logic Controllers), motor drives, sensors, and other industrial control systems. Its robust construction, high current and voltage ratings, and reliable performance make it suitable for demanding industrial applications.

Telecommunications: The Solder Cup Power D-Sub Connector is utilized in telecommunications equipment and systems. It is commonly found in networking devices, communication modules, and telecom infrastructure. The connector's ability to handle high current and voltage, coupled with its secure and stable connection, makes it an ideal choice for transmitting signals in telecommunication networks.

Automotive and Transportation: The Solder Cup Power D-Sub Connector is also used in the automotive and transportation industry. It is utilized in various applications such as vehicle wiring systems, engine control units, and electronic control modules. The connector's ability to handle high current and voltage, along with its durable construction, makes it suitable for the demanding environment of automotive and transportation applications.

Aerospace and Defense: The Solder Cup Power D-Sub Connector finds applications in the aerospace and defense sectors. It is commonly used in avionics systems, military equipment, and communication systems. The connector's high reliability, robustness, and ability to handle high current and voltage make it suitable for the stringent requirements of aerospace and defense applications.

In conclusion, the Solder Cup Power D-Sub Connector serves a wide range of purposes and finds applications in various industries. Its ability to handle high current and voltage, along with its reliable performance, makes it a popular choice for power and signal transmission in industrial automation, telecommunications, automotive, aerospace, and defense applications.4. How durable and reliable is it?

The Solder Cup Power D-Sub Connector is known for its durability and reliability, making it a popular choice for a wide range of applications in various industries. Here is an in-depth introduction to the durability and reliability of the Solder Cup Power D-Sub Connector:

Durability:

The Solder Cup Power D-Sub Connector is constructed using high-quality materials such as metal shells, insulating materials, and solder cups that are designed to withstand mechanical stress, environmental factors, and repetitive use. The metal shells provide robust protection to the internal components of the connector, ensuring its durability in harsh conditions.

The solder cups of the connector are designed to securely hold the wires or cables in place, even under vibrations or movements. This ensures a stable connection that is resistant to loosening or breakage over time. Additionally, the connector's overall design and construction are engineered to meet industry standards for durability and longevity.

Reliability:

The Solder Cup Power D-Sub Connector is widely recognized for its high reliability in providing consistent and uninterrupted power and signal transmission. The connector's solder cups create a strong and reliable connection between the wires and contacts, minimizing the risk of signal loss or disruptions.

Moreover, the Solder Cup Power D-Sub Connector undergoes rigorous testing and quality assurance processes during manufacturing to ensure that it meets performance standards and specifications. This helps to guarantee its reliability in diverse applications where stable electrical connections are essential.

The connector's ability to handle high current and voltage levels without compromising its performance further enhances its reliability in demanding environments. Whether used in industrial automation, telecommunications, automotive, or aerospace applications, the Solder Cup Power D-Sub Connector is trusted for its consistent performance and reliability.

In conclusion, the Solder Cup Power D-Sub Connector is renowned for its durability and reliability in providing secure and stable connections for power and signal transmission. Its robust construction, high-quality materials, and stringent testing procedures make it a dependable choice for applications that require long-lasting and reliable electrical connections.5. How does it work?

The Solder Cup Power D-Sub Connector is a versatile and widely used connector that provides a reliable and secure connection for power and signal transmission. Here is a detailed explanation of how it works:

Connector Structure: The Solder Cup Power D-Sub Connector consists of a metal shell, contacts, insulating materials, and solder cups. The metal shell acts as a protective housing for the internal components and provides mechanical strength and durability. The insulating materials, typically made of high-quality plastics, ensure electrical insulation and prevent short circuits between contacts. The solder cups are designed to hold the stripped ends of wires or cables securely. This allows for a strong and reliable connection.

Soldering Process: The solder cups play a crucial role in the functioning of the connector. To create a connection, the wires or cables are stripped of their insulation, and the exposed conductive cores are inserted into the solder cups. The wires are then soldered to the cups using a soldering iron or a specialized soldering machine. The solder forms a permanent bond between the wires and the cups, creating a secure electrical connection.

Contact Design: The Solder Cup Power D-Sub Connector typically features a range of contacts, including power contacts, signal contacts, and ground contacts. These contacts are strategically positioned within the connector to ensure proper alignment and mating with the corresponding contacts in the mating connector. The contacts are made of high-quality materials, such as copper or gold-plated copper, to provide excellent conductivity and minimize signal loss.

Mating and Locking: The Solder Cup Power D-Sub Connector is designed to mate with a compatible connector, which may be another Solder Cup Power D-Sub Connector or a different type of D-Sub Connector. The mating process involves aligning the connectors and applying force to connect them. Once connected, the connectors are secured using locking mechanisms, such as screws or latches, to prevent accidental disconnection.

Power and Signal Transmission: The Solder Cup Power D-Sub Connector is capable of transmitting both power and signals. The power contacts can handle high current and voltage levels, making them suitable for power transmission applications. The signal contacts are designed to provide a reliable connection for transmitting control signals, data signals, and communication signals. The connector's design ensures minimal signal loss and interference, resulting in a stable and high-quality transmission.

In conclusion, the Solder Cup Power D-Sub Connector works by securely connecting wires or cables to the solder cups, creating a reliable electrical connection. Its robust structure, soldering process, contact design, and mating capabilities make it a versatile and efficient solution for power and signal transmission in various industries and applications.6. How to install and use?

Installing and using a Solder Cup Power D-Sub Connector is a straightforward process that involves a few key steps to ensure a secure and reliable connection for power and signal transmission. Here is a detailed guide on how to install and use a Solder Cup Power D-Sub Connector:

Preparation: Before installing the Solder Cup Power D-Sub Connector, gather all the necessary tools and materials, including the connector itself, wires or cables to be connected, a soldering iron, solder, wire strippers, and any other tools required for the job.

Stripping Wires: Begin by stripping the insulation from the ends of the wires or cables that will be connected to the Solder Cup Power D-Sub Connector. Use wire strippers to carefully remove the insulation, exposing the conductive cores of the wires.

Soldering: Insert the stripped ends of the wires into the solder cups of the connector. Apply heat from a soldering iron to the solder cups and wires while feeding solder into the joint. Ensure that the solder forms a secure bond between the wires and the cups. Be careful not to overheat the connector or apply too much solder, as this can lead to poor connections.

Securing the Connection: Once the wires are soldered to the cups, ensure that the connection is secure and there are no loose wires. Use a multimeter to check for continuity and verify that the connections are properly made.

Mating the Connectors: To use the Solder Cup Power D-Sub Connector, mate it with a compatible connector by aligning the pins or contacts and applying gentle pressure to connect them. Use any locking mechanisms, such as screws or latches, to secure the connection and prevent accidental disconnection.

Testing: After the connectors are mated, test the connection to ensure proper power and signal transmission. Verify that there is continuity between the connected devices and that signals are being transmitted accurately.

Maintenance: Regularly inspect the Solder Cup Power D-Sub Connector for any signs of wear or damage. Clean the connector periodically to remove any dust or debris that may affect its performance. Ensure that the solder joints are intact and re-solder any connections that may have come loose.

In conclusion, installing and using a Solder Cup Power D-Sub Connector involves stripping, soldering, securing, mating, testing, and maintaining the connector to ensure reliable power and signal transmission. By following these steps carefully and ensuring proper installation, you can create a secure and stable connection for your electrical applications.

-

1.What is the size, current and voltage rating of this connector?

The Floating Board To Board Connector is a versatile and widely used component in the electronics industry. It is designed to establish connections between circuit boards, allowing for the transmission of signals and power between them. Here is a comprehensive introduction to the Floating Board To Board Connector, including its size, current rating, and voltage rating.

Size: The Floating Board To Board Connector comes in various sizes to accommodate different application requirements. It is available in different pitch sizes, typically ranging from 0.5mm to 2.54mm. The pitch size refers to the distance between adjacent pins or contacts on the connector. The connector's overall dimensions may vary depending on the specific model and configuration.

Current Rating: The Floating Board To Board Connector is designed to handle different levels of current, depending on the specific model and configuration. The current rating of the connector is determined by factors such as the size and material of the contact pins, the contact resistance, and the temperature rise. Generally, the current rating can range from a few milliamps to several amps, allowing for a wide range of applications.

Voltage Rating: The Floating Board To Board Connector is designed to withstand specific levels of voltage without insulation breakdown or arcing. The voltage rating of the connector is determined by factors such as the dielectric strength of the materials used, the spacing between contacts, and the design of the insulation. The voltage rating can vary depending on the specific model and configuration, ranging from a few volts to several hundred volts.

It is important to note that the size, current rating, and voltage rating of the Floating Board To Board Connector may vary depending on the manufacturer and specific product series. It is essential to consult the product datasheet or contact the manufacturer for detailed specifications and ratings for a specific connector model.

In conclusion, the Floating Board To Board Connector is a versatile component used for establishing connections between circuit boards. Its size, current rating, and voltage rating may vary depending on the specific model and configuration. The connector's specifications determine its compatibility with different applications, and it is crucial to consider these factors when selecting and using the Floating Board To Board Connector in electronic designs.2. Are there different socket types to choose from?

Floating Board To Board Connectors are available in a variety of socket types to cater to different application requirements and design preferences. These socket types offer unique features and advantages, allowing designers to select the most suitable option for their specific needs. Here is a comprehensive overview of the different socket types available for Floating Board To Board Connectors:

Standard Socket: The standard socket type is the most common option for Floating Board To Board Connectors. It features a simple design with straight pins or contacts that provide a secure and reliable connection between circuit boards. Standard sockets are available in various pitch sizes to accommodate different spacing requirements between boards.

SMT Socket: Surface Mount Technology (SMT) sockets are designed for easy and efficient surface mounting on the circuit board. These sockets have solder pads instead of through-hole pins, allowing for automated assembly processes and saving space on the board. SMT sockets provide a low-profile solution for compact electronic designs.

Right-Angle Socket: Right-angle sockets are designed to create connections between circuit boards at a right angle. This configuration is useful when space constraints or specific board orientations require a perpendicular mating arrangement. Right-angle sockets ensure a secure connection while optimizing the use of available board space.

Stacked Socket: Stacked sockets feature multiple rows of contacts stacked on top of each other. This design allows for higher-density connections between boards, enabling designers to maximize the number of connections in a limited space. Stacked sockets are ideal for applications that require a high number of signal paths or data lines.

Floating Socket: Floating sockets provide a degree of freedom in the lateral movement of the connected boards. This flexibility compensates for any misalignment or thermal expansion between the boards, ensuring a reliable and stable connection. Floating sockets are suitable for applications where board alignment may vary due to mechanical stress or temperature fluctuations.

High-Speed Socket: High-speed sockets are designed to support high-frequency signal transmission between boards. These sockets feature optimized signal integrity characteristics, such as controlled impedance and reduced crosstalk, to maintain signal integrity in high-speed data transfers. High-speed sockets are ideal for applications that require reliable data communication at high data rates.

In conclusion, Floating Board To Board Connectors offer a range of socket types to suit different design requirements, including standard, SMT, right-angle, stacked, floating, and high-speed sockets. Designers can choose the appropriate socket type based on factors such as space constraints, alignment needs, signal integrity requirements, and ease of assembly. Selecting the right socket type is essential to ensure a successful and efficient board-to-board connection in electronic designs.3.Main purposes and application areas

Floating Board To Board Connectors are widely used in various industries and applications where the establishment of reliable and secure connections between circuit boards is crucial. Here is a comprehensive overview of the main purposes and application areas of Floating Board To Board Connectors:

Consumer Electronics: Floating Board To Board Connectors are extensively used in consumer electronics devices such as smartphones, tablets, laptops, and gaming consoles. These connectors enable the interconnection of different circuit boards within these devices, facilitating the transmission of signals and power.

Automotive: Automotive applications require robust and reliable connectors to ensure the proper functioning of various electronic components. Floating Board To Board Connectors are utilized in automotive systems for applications such as infotainment systems, dashboard displays, advanced driver-assistance systems (ADAS), and engine control units (ECU).

Industrial Equipment: Floating Board To Board Connectors find application in industrial equipment and machinery, where they enable the connection of control boards, sensors, and actuators. These connectors are commonly used in robotics, automation systems, machine vision systems, and control panels.

Telecommunications: Floating Board To Board Connectors play a vital role in the telecommunications industry, providing connectivity solutions for network equipment, switches, routers, and base stations. These connectors ensure reliable data transmission and signal integrity in high-speed and high-frequency telecommunications applications.

Medical Devices: Medical devices require connectors that can withstand harsh environments and ensure secure connections. Floating Board To Board Connectors are used in medical equipment such as patient monitoring systems, imaging equipment, diagnostic devices, and surgical instruments. They provide the necessary connectivity for the proper functioning of these critical devices.

Aerospace and Defense: Floating Board To Board Connectors are utilized in aerospace and defense applications where high reliability and ruggedness are required. These connectors are used in avionics systems, satellite communication systems, military vehicles, and radar systems.

LED Lighting: Floating Board To Board Connectors are employed in LED lighting applications, connecting LED driver boards to LED modules or strips. These connectors enable the transmission of power and control signals, ensuring efficient and reliable operation of LED lighting systems.

Renewable Energy: Floating Board To Board Connectors are used in renewable energy systems such as solar power and wind power generation. These connectors facilitate the interconnection of control boards and power electronics, enabling efficient energy conversion and management.

In conclusion, Floating Board To Board Connectors have a wide range of applications in various industries, including consumer electronics, automotive, industrial equipment, telecommunications, medical devices, aerospace and defense, LED lighting, and renewable energy. These connectors play a crucial role in establishing reliable connections between circuit boards, ensuring the proper functioning of electronic systems and devices.4. How durable and reliable is it?

Floating Board To Board Connectors are known for their durability and reliability, making them a popular choice for various electronic applications. Here is a comprehensive description of the durability and reliability features of Floating Board To Board Connectors:

Materials: Floating Board To Board Connectors are typically manufactured using high-quality materials such as stainless steel, phosphor bronze, and high-temperature resistant plastics. These materials offer excellent durability, ensuring the connectors can withstand mechanical stress, temperature variations, and environmental factors.

Contact Design: Floating Board To Board Connectors feature well-designed contact points that provide a secure and reliable connection. The contact pins or pads are often plated with materials such as gold or palladium to enhance their conductivity and corrosion resistance. This ensures a long-lasting and reliable connection between the boards.

Shock and Vibration Resistance: Floating Board To Board Connectors are designed to withstand shock and vibration, which are common occurrences in many applications. The connectors often have features such as locking mechanisms or additional support structures to prevent accidental disconnection due to external forces.

Environmental Resistance: Floating Board To Board Connectors are engineered to resist various environmental factors such as moisture, dust, and chemicals. They may have sealing features or use materials that provide protection against these elements, ensuring reliable performance even in challenging environments.

Lifecycle and Durability Testing: Manufacturers subject Floating Board To Board Connectors to extensive lifecycle and durability testing to ensure their performance under real-world conditions. These tests simulate repeated mating and unmating cycles, temperature variations, and exposure to different environmental factors. Connectors that pass these tests are considered highly durable and reliable.

Quality Control: Floating Board To Board Connectors undergo strict quality control measures during their manufacturing process. Manufacturers often implement stringent quality assurance practices such as ISO certifications and in-house testing procedures to ensure the connectors meet industry standards and customer expectations.

Industry Compliance: Floating Board To Board Connectors are designed and manufactured to comply with industry standards and regulations. Compliance with standards such as UL, RoHS, and REACH ensures that the connectors are safe, reliable, and environmentally friendly.

In conclusion, Floating Board To Board Connectors are known for their durability and reliability. They are designed using high-quality materials, feature well-engineered contact points, and undergo rigorous testing and quality control measures. These connectors can withstand mechanical stress, temperature variations, shock, vibration, and environmental factors, providing a long-lasting and secure connection between circuit boards.5. How does it work?

Floating Board To Board Connectors work by providing a secure and reliable electrical connection between two circuit boards. These connectors consist of two main components: the socket, which is attached to one circuit board, and the header, which is attached to the other circuit board.

The socket and header are designed to fit together, creating a mating interface for the connection. The socket typically has a series of pins or contacts, while the header has corresponding slots or receptacles. When the socket and header are properly aligned, the pins or contacts on the socket make contact with the slots or receptacles on the header, creating an electrical pathway between the two circuit boards.

The pins or contacts on the socket are usually spring-loaded, allowing for a certain degree of movement or float. This float enables the connectors to compensate for any misalignment or thermal expansion between the circuit boards. It helps maintain a reliable and stable connection, even in dynamic or changing conditions.

To establish the connection, the circuit boards are aligned and brought together, allowing the pins or contacts on the socket to enter the slots or receptacles on the header. Once the connection is made, the pins or contacts exert a force on the slots or receptacles, ensuring a secure and stable electrical connection.

Floating Board To Board Connectors can be used in various applications, such as consumer electronics, automotive systems, industrial equipment, telecommunications, medical devices, aerospace and defense, LED lighting, and renewable energy. The connectors are designed to accommodate different spacing requirements, orientations, and signal integrity needs, depending on the specific application.

In summary, Floating Board To Board Connectors work by providing a reliable and secure electrical connection between two circuit boards. They use spring-loaded pins or contacts to establish the connection and allow for a certain degree of movement or float to compensate for misalignment or thermal expansion. These connectors play a crucial role in enabling the seamless integration and functioning of electronic devices and systems.6. How to install and use?

Installing and using Floating Board To Board Connectors is a straightforward process that requires careful attention to ensure a proper and secure connection. Here are the steps to install and use Floating Board To Board Connectors:

Preparation: Before installing the connectors, ensure that the circuit boards are clean and free from any debris or contaminants. This will help to establish a reliable and stable connection.

Connector Selection: Choose the appropriate Floating Board To Board Connector for your specific application. Consider factors such as pitch, orientation, and the number of contacts required.

Aligning the Connector: Place the socket connector on one circuit board and the header connector on the other circuit board. Make sure the connectors are properly aligned, ensuring that the pins or contacts on the socket line up with the slots or receptacles on the header.

Connection: Gently press the two circuit boards together, allowing the pins or contacts on the socket to enter the slots or receptacles on the header. Apply even pressure to ensure a secure and reliable connection. If necessary, use a magnifying glass or microscope to verify that all pins or contacts are properly aligned and inserted.

Locking Mechanism: Some Floating Board To Board Connectors feature locking mechanisms to provide additional stability and prevent accidental disconnection. If your connector has a locking feature, engage it according to the manufacturer's instructions.

Testing: Once the connection is established, test the electrical continuity and signal integrity between the circuit boards using appropriate testing equipment. This will help to ensure that the connection is reliable and that there are no issues with signal transmission.

Regular Inspection: It is important to regularly inspect the connectors for any signs of damage or wear. Check for loose pins or contacts, bent or broken parts, or any other abnormalities. If any issues are found, replace the connectors to maintain a reliable connection.

Removal: When removing Floating Board To Board Connectors, use caution to avoid damaging the circuit boards or the connectors themselves. Gently separate the two circuit boards, ensuring that no excessive force is applied.

In conclusion, installing and using Floating Board To Board Connectors involves aligning the connectors, pressing the circuit boards together, and ensuring a secure connection. Regular inspection and testing are essential to maintain the reliability of the connection. By following these steps, you can successfully install and use Floating Board To Board Connectors in various electronic applications.

-

1.What is the size, current and voltage rating of this connector?

2.0mm Hard Metric Connectors are a type of board-to-board connector that is widely used in various industries for their small size, high-density, and reliable performance. These connectors are designed to provide a compact and efficient solution for connecting circuit boards in applications where space is limited.

In terms of size, 2.0mm Hard Metric Connectors have a pitch of 2.0mm, which refers to the distance between the centerlines of adjacent pins. The compact size of these connectors allows for high-density packaging, making them ideal for applications that require a large number of connections in a limited space.

The current and voltage rating of 2.0mm Hard Metric Connectors can vary depending on the specific design and manufacturer. However, these connectors are typically rated for moderate to high current and voltage levels. The current rating can range from a few amps to several tens of amps, depending on the size and design of the connector. The voltage rating can range from a few volts to several hundred volts, depending on the insulation properties and design of the connector.

It is important to note that the current and voltage ratings of a connector are specified by the manufacturer and should be carefully considered when selecting a connector for a particular application. It is crucial to choose a connector with a current and voltage rating that is appropriate for the specific requirements of the application to ensure safe and reliable operation.

In addition to size, current, and voltage ratings, 2.0mm Hard Metric Connectors may also have other features and specifications that enhance their performance and reliability. These may include gold-plated contacts for improved conductivity and corrosion resistance, shielded designs to minimize electromagnetic interference, and various locking mechanisms to ensure a secure and vibration-resistant connection.

Overall, 2.0mm Hard Metric Connectors offer a compact and reliable solution for board-to-board connections in applications where space is limited. Their small size, high-density packaging, and moderate to high current and voltage ratings make them suitable for a wide range of industries, including telecommunications, industrial automation, computer systems, and consumer electronics. By carefully considering the size, current, and voltage rating, as well as other features, engineers can choose the appropriate 2.0mm Hard Metric Connector for their specific application, ensuring a reliable and efficient connection between circuit boards.2. Are there different socket types to choose from?

Yes, there are different socket types available for 2.0mm Hard Metric Connectors. These socket types offer flexibility and versatility in board-to-board connections, allowing engineers to choose the most suitable option for their specific application requirements.

One common type of socket used in 2.0mm Hard Metric Connectors is the straight socket. This type of socket has pins that are oriented perpendicular to the circuit board, providing a direct connection between two boards in a straight line. Straight sockets are ideal for applications where a simple and straightforward board-to-board connection is needed.

Another type of socket is the right-angle socket. This type of socket has pins that are oriented at a right angle to the circuit board. Right-angle sockets are often used when boards need to be connected at a 90-degree angle or when space constraints require a compact and space-saving design. This allows for more flexibility in board placement and routing.

Furthermore, there are also surface mount sockets available for 2.0mm Hard Metric Connectors. Surface mount sockets are designed to be mounted directly on the surface of the circuit board, eliminating the need for through-hole soldering. They provide a more convenient and efficient solution for high-density board-to-board connections, as they can be easily placed and soldered using automated assembly processes.

Additionally, hybrid sockets are available, which combine the features of both straight and right-angle sockets. Hybrid sockets provide greater flexibility in board placement and orientation, allowing for connections at different angles and orientations within the same connector system.

It is important to consider the specific application requirements, including board layout and space constraints, when selecting the appropriate socket type for 2.0mm Hard Metric Connectors. Engineers should also consider factors such as the number of pins required, mating force, and the overall durability and reliability of the connector system.

In conclusion, 2.0mm Hard Metric Connectors offer a range of socket types to choose from, including straight sockets, right-angle sockets, surface mount sockets, and hybrid sockets. These socket types provide flexibility and versatility in board-to-board connections, allowing engineers to select the most suitable option for their specific application needs.3.Main purposes and application areas

2.0mm Hard Metric Connectors are widely used in various industries and applications due to their versatility and reliability. These connectors offer a reliable and efficient solution for board-to-board and wire-to-board connections.

One of the main purposes of 2.0mm Hard Metric Connectors is to provide a connection interface between printed circuit boards (PCBs). They allow for the secure and stable transfer of signals, power, and data between different boards in electronic devices. These connectors are commonly used in applications such as telecommunications equipment, computer systems, industrial automation, medical devices, and automotive electronics.

In the telecommunications industry, 2.0mm Hard Metric Connectors are used in networking and communication equipment, including routers, switches, and servers. These connectors provide high-speed transmission of signals and data, ensuring reliable and efficient communication.

In computer systems, 2.0mm Hard Metric Connectors are utilized in motherboards, expansion cards, and peripheral devices. They enable the connection between different components, such as processors, memory modules, graphics cards, and storage devices. These connectors ensure the smooth operation and data transfer within the computer system.

Industrial automation is another key area where 2.0mm Hard Metric Connectors find extensive use. They are employed in control systems, PLCs (Programmable Logic Controllers), and industrial machinery. These connectors provide a reliable and secure connection between various sensors, actuators, and control modules, ensuring the efficient operation of the automated systems.

In the medical field, 2.0mm Hard Metric Connectors are utilized in medical devices and equipment. They are commonly found in patient monitoring systems, diagnostic equipment, and medical imaging devices. These connectors enable the transfer of signals and data, allowing for accurate monitoring and diagnosis of patients.

Automotive electronics also rely on 2.0mm Hard Metric Connectors for their electrical and electronic systems. These connectors are used in applications such as infotainment systems, engine control units, lighting systems, and advanced driver-assistance systems (ADAS). They provide a reliable and robust connection, ensuring the safe and efficient operation of the vehicle's electronic systems.

Overall, 2.0mm Hard Metric Connectors play a crucial role in various industries and applications. With their durability, reliability, and versatility, these connectors provide a reliable and efficient solution for board-to-board and wire-to-board connections, enabling the seamless transfer of signals, power, and data in electronic devices and systems.4. How durable and reliable is it?

2.0mm Hard Metric Connectors are highly regarded for their durability and reliability. These connectors are designed to withstand demanding operating conditions and provide a long-lasting and stable connection between circuit boards.

The durability of 2.0mm Hard Metric Connectors can be attributed to a combination of factors. Firstly, they are constructed using high-quality materials such as high-temperature thermoplastics and metal alloys. These materials offer excellent mechanical strength and resistance to wear and tear, ensuring that the connectors can withstand the rigors of daily use. Additionally, the pins and contacts of these connectors are often gold-plated, enhancing their durability by providing corrosion resistance and ensuring reliable electrical conductivity.

Moreover, 2.0mm Hard Metric Connectors are specifically engineered to withstand high levels of vibration and shock. They feature robust locking mechanisms such as latches or screws that keep the connectors securely in place, preventing accidental disconnections. This ensures a stable and reliable connection even in demanding environments where vibrations and shocks are common, such as in automotive or industrial applications.

In addition to their physical durability, 2.0mm Hard Metric Connectors are designed to provide reliable electrical performance. The contact design and materials used in these connectors minimize contact resistance, ensuring a low insertion force and reliable electrical connection. The connectors are often rated for high current and voltage levels, allowing them to handle demanding power requirements.

To ensure the reliability of 2.0mm Hard Metric Connectors, they undergo rigorous testing and quality control processes during manufacturing. These connectors are tested for factors such as mechanical strength, electrical performance, and temperature resistance. Compliance with industry standards and certifications further ensures their reliability.

It is important to note that the overall durability and reliability of 2.0mm Hard Metric Connectors can also depend on factors such as proper installation, maintenance, and the quality of the mating connectors. Following manufacturer guidelines and using compatible connectors will help ensure optimal performance and longevity.

In summary, 2.0mm Hard Metric Connectors are highly durable and reliable. Their robust construction, secure locking mechanisms, and high-quality materials contribute to their ability to withstand harsh environments and provide a stable and long-lasting connection. These connectors are trusted in various industries where reliability and durability are critical, such as telecommunications, industrial automation, and automotive applications.

5. How does it work?

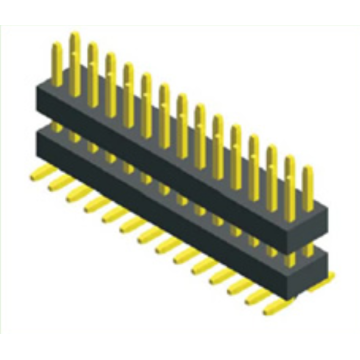

2.0mm Hard Metric Connectors are designed to provide a reliable and efficient connection between circuit boards. They consist of male and female connector components that are specifically designed to interlock and create a secure electrical connection.

The working principle of 2.0mm Hard Metric Connectors is relatively straightforward. The male connector, also known as the pin header, is mounted onto one circuit board, while the female connector, also known as the receptacle, is mounted on the other circuit board. The male pins of the pin header are aligned with the corresponding female sockets of the receptacle.

To establish a connection, the two boards are brought together, aligning the male and female connectors. Once aligned, the male pins are inserted into the female sockets, creating a complete electrical connection. The pins and sockets are designed to have a tight fit, ensuring a secure and stable connection.

The pins of the male connector are typically made of conductive materials such as copper or brass, while the sockets of the female connector are made of a conductive material such as phosphor bronze. In some cases, the pins and sockets may be gold-plated to enhance conductivity and prevent corrosion.

2.0mm Hard Metric Connectors often feature a locking mechanism to ensure that the connection remains secure. This can be in the form of a latch, screw, or other locking mechanism. Once the connectors are fully inserted and locked, they will remain securely connected until intentionally disconnected.

These connectors are designed to handle high-speed data transmission, high power, and high-frequency signals. They provide a reliable and stable connection, minimizing signal loss and interference.

The modular design of 2.0mm Hard Metric Connectors allows for easy installation and removal, making them suitable for applications where frequent board-to-board connections are required. They are also designed to withstand various environmental conditions, such as temperature fluctuations, vibrations, and shocks, ensuring reliable performance in demanding applications.

In summary, 2.0mm Hard Metric Connectors work by interlocking male and female connector components to establish a secure and stable electrical connection between circuit boards. Their modular design, durability, and reliability make them a popular choice for a wide range of applications in industries such as telecommunications, industrial automation, and automotive electronics.6. How to install and use?

Installing and using 2.0mm Hard Metric Connectors is a relatively straightforward process. Here is a step-by-step guide on how to install and use these connectors:

Prepare the circuit boards: Ensure that the circuit boards you intend to connect are clean and free from any dust, debris, or contaminants. This will help ensure a reliable and secure connection.

Position the male and female connectors: Identify the male and female connectors on the respective circuit boards. The male connector, also known as the pin header, is usually mounted on one circuit board, while the female connector, known as the receptacle, is mounted on the other circuit board.

Align the connectors: Carefully align the male and female connectors so that the pins of the male connector are in line with the corresponding sockets of the female connector. Take caution to align them properly to avoid any damage to the pins or sockets.

Insert the pins into the sockets: Once the connectors are aligned, gently insert the pins of the male connector into the sockets of the female connector. Apply even pressure to ensure a smooth insertion. Make sure that the pins are fully inserted into the sockets for a secure connection.

Lock the connectors: If your 2.0mm Hard Metric Connectors have a locking mechanism, such as a latch or a screw, activate it to secure the connection. This will prevent any accidental disconnections caused by vibrations or movement.

Test the connection: Once the connectors are installed and locked, it is essential to test the connection to ensure it is secure and functional. Use appropriate testing equipment or procedures to verify that the signals, power, or data are being transmitted accurately between the connected circuit boards.

Proper handling and maintenance: To ensure the optimal performance and longevity of the connectors, handle them with care and avoid applying excessive force or pressure. Regularly inspect the connectors for any signs of damage or wear and clean them if necessary. Follow the manufacturer's guidelines for proper maintenance and handling.

Remember that proper installation and usage of 2.0mm Hard Metric Connectors are crucial to maintaining a reliable and secure connection. Following the steps outlined above and adhering to manufacturer guidelines will help ensure the connectors' optimal performance and longevity.

In summary, installing and using 2.0mm Hard Metric Connectors involves aligning the male and female connectors, inserting the pins into the sockets, locking the connectors if applicable, testing the connection, and practicing proper handling and maintenance. These connectors provide a reliable and efficient solution for board-to-board and wire-to-board connections in various industries and applications.

-

The battery connector is one of the key components in the battery system and is used to connect the battery to the circuit. With the continuous progress and development of science and technology, the technology of battery connectors is also constantly updated and improved. Here are a few key trends on battery connector technology:

1. Miniaturization: In order to improve the integration and compactness of the battery system, the battery connector is also gradually developing in the direction of miniaturization. By reducing the size and weight of the connector, you can reduce the space footprint inside the battery pack and reduce costs.

2. New battery interface: With the rapid development of electric vehicles, renewable energy and other fields, the requirements for battery performance are getting higher and higher. Therefore, new battery interface technologies are being researched and developed, such as nanomaterial coatings, conductive polymers, etc., to improve the conductivity and durability of batteries.

3. Low contact impedance: In the battery system, the contact resistance is an important parameter, which directly affects the energy conversion efficiency of the battery. To reduce contact resistance, researchers are exploring the use of novel materials to make thinner, softer connector contacts, as well as more efficient circuit designs to reduce current loss.

4. High connection reliability: Because battery connectors need to withstand extreme environmental conditions such as high temperature, high pressure and high energy density, high reliability is very important. For this reason, many manufacturers are developing connector materials and technologies with characteristics such as oxidation resistance, corrosion resistance and wear resistance to ensure their long-term stable operation.

In short, the future development trend of battery connectors will be more miniaturized, with better battery interfaces, low contact impedance and high connection reliability products. These technologies will help improve the efficiency and performance of battery systems and provide better support for future energy transitions.

-

1.What is the size, current and voltage rating of this connector?

The DIN41612 connector is a type of electrical connector that is widely used in a variety of electronic applications. It is known for its high reliability and versatile design. The connector is named after the Deutsches Institut für Normung (DIN), the German standardization organization that established the specifications for this type of connector.

In terms of size, the DIN41612 connector typically comes in different variations, including 32, 48, 64, 96, and 128 contact positions. The size and number of contacts can vary depending on the specific application requirements. The connector is designed to provide a secure and stable connection between various electronic components, such as printed circuit boards (PCBs) and other electrical devices.

The current and voltage rating of the DIN41612 connector depends on the specific version and configuration. Generally, the connector is capable of handling moderate to high levels of current and voltage. The current rating can range from a few milliamperes (mA) up to several amperes (A), depending on the size and design of the contacts. Similarly, the voltage rating can vary from a few volts (V) to several hundred volts (V), again depending on the specific version and configuration.

The DIN41612 connector is widely used in applications such as telecommunications, computer systems, industrial equipment, and automotive electronics. Its versatility and reliability make it suitable for a wide range of electronic devices and systems. The connector is designed to withstand the demands of harsh environments, including temperature variations, vibrations, and mechanical stress.

One notable feature of the DIN41612 connector is its modular design, which allows for easy customization and expansion. The connector can be easily modified by adding or removing contact modules, allowing for flexibility in terms of the number of connections and pin configurations. This modular design makes the DIN41612 connector highly adaptable to different application requirements.

In addition, the DIN41612 connector is designed to provide excellent electrical performance, ensuring low contact resistance and high signal integrity. The connector utilizes a reliable contact system, which ensures a secure and stable connection even in high-vibration environments. The contacts are typically made of high-quality materials such as gold-plated copper alloy, which offers excellent conductivity and corrosion resistance.

In summary, the DIN41612 connector is a versatile and reliable electrical connector that is widely used in various electronic applications. Its modular design, size variations, and high electrical performance make it suitable for a wide range of devices and systems. The connector's current and voltage ratings depend on the specific version and configuration, allowing for flexibility in meeting different application requirements.2. Are there different socket types to choose from?

The DIN41612 connector offers various socket types to choose from, providing flexibility and compatibility with different system requirements. These socket types are designed to accommodate specific pin configurations and provide reliable connections.

One commonly used socket type is the Type C socket. It features a 2.54mm pitch and is widely used in applications such as telecommunications and industrial equipment. The Type C socket typically offers a high number of contact positions, ranging from 32 to 160, allowing for a wide range of connections.

Another commonly used socket type is the Type R socket. It features a 2.0mm pitch and is often used in applications that require a high-density connection. The Type R socket is available in various contact position options, ranging from 16 to 160, providing flexibility for different system requirements.

In addition to Type C and Type R sockets, there are also other socket types available, such as Type B and Type D. These socket types have different pitch sizes and contact arrangements, offering flexibility for specific application needs. Type B sockets, for example, feature a 5.08mm pitch and are commonly used in power applications due to their ability to handle higher current ratings.

The DIN41612 connector's socket types are designed to ensure reliable and stable connections. They are typically made of high-quality materials, such as thermoplastic or thermosetting insulators, and feature durable metal contacts. The contacts are often gold plated to enhance conductivity and corrosion resistance, ensuring excellent electrical performance.

It's important to note that the selection of socket type depends on the specific requirements of the application. Factors such as the number of contact positions, pitch size, current rating, and space limitations should be considered when choosing the appropriate socket type for a particular system.

Overall, the DIN41612 connector offers a range of socket types to choose from, providing versatility and adaptability for different applications. Whether it's for telecommunications, industrial equipment, or power applications, the DIN41612 connector's socket types can accommodate various pin configurations and provide reliable connections for optimal system performance.3.Main purposes and application areas

The DIN 41612 connector, also known as the Deutsches Institut für Normung (German Institute for Standardization) 41612 connector, is a widely used standard connector in the electronics industry. It is a type of rectangular connector that follows the DIN standards for dimensions and electrical characteristics. The DIN 41612 connector is known for its reliability, versatility, and compatibility with a wide range of applications.

The main purposes of the DIN 41612 connector include:

Signal Transmission: The DIN 41612 connector is designed to facilitate the transmission of electrical signals between different electronic devices or components. It provides a secure and stable connection for signals to pass through, ensuring efficient communication within a system.

Power Distribution: In addition to signal transmission, the DIN 41612 connector is also used for power distribution purposes. It allows for the safe and efficient transfer of power between connected devices, ensuring a reliable power supply for the system.

Board-to-Board Connections: The DIN 41612 connector is commonly used for board-to-board connections in electronic devices. It enables the connection of different circuit boards within a system, allowing for the exchange of data and signals between various components.

Modular Design: The DIN 41612 connector features a modular design that allows for easy installation and maintenance. Its versatile layout and configuration options make it suitable for a wide range of applications and system designs.

The DIN 41612 connector finds application in various industries and areas, including:

Telecommunications: The DIN 41612 connector is commonly used in telecommunications equipment such as routers, switches, and communication systems. It enables the connection of different modules and components, supporting data transmission and signal processing.

Industrial Automation: In industrial automation systems, the DIN 41612 connector is utilized for connecting control panels, sensors, and other devices. It helps establish communication between different components, enabling efficient and automated operation.

Computer Systems: The DIN 41612 connector is widely used in computer systems for connecting expansion cards, memory modules, and other peripherals to the motherboard. It ensures a reliable and secure connection for data transfer and system operation.

Test and Measurement Equipment: The DIN 41612 connector is also utilized in test and measurement equipment for connecting various instruments and devices. It provides a standardized interface for data transfer and signal processing.

In summary, the DIN 41612 connector is a versatile and reliable connector that serves multiple purposes in the electronics industry. Its standardized design, compatibility with different applications, and wide range of applications make it a popular choice for engineers and designers working on electronic systems and devices.

4. How durable and reliable is it?

The DIN41612 connector is known for its durability and reliability, making it highly suitable for various electronic applications. This connector is designed to withstand harsh environments and provide a stable and secure connection over an extended period.

One of the key factors that contribute to the durability of the DIN41612 connector is its construction. The connector is typically made of high-quality materials, such as thermoplastic or thermosetting insulators, which provide excellent mechanical strength and resistance to temperature variations. The metal contacts used in the connector are often made of materials like copper alloy, which offer good conductivity and corrosion resistance.

The DIN41612 connector is designed to meet demanding performance requirements. It features a reliable contact system that ensures low contact resistance and high signal integrity. The contacts are often gold-plated to enhance conductivity and prevent oxidation, ensuring long-term reliability.